Efficient sludge pumping depends heavily on the design of the impeller inside a sludge pump. The impeller determines how effectively the pump handles solids, resists clogging, and maintains energy efficiency in challenging environments. Whether operating a surface-mounted unit or a submersible sludge pump, understanding how impeller type, size, and design features impact performance is crucial for selecting the right equipment and avoiding costly downtime.

Understanding Sludge Pumps and Their Operational Challenges

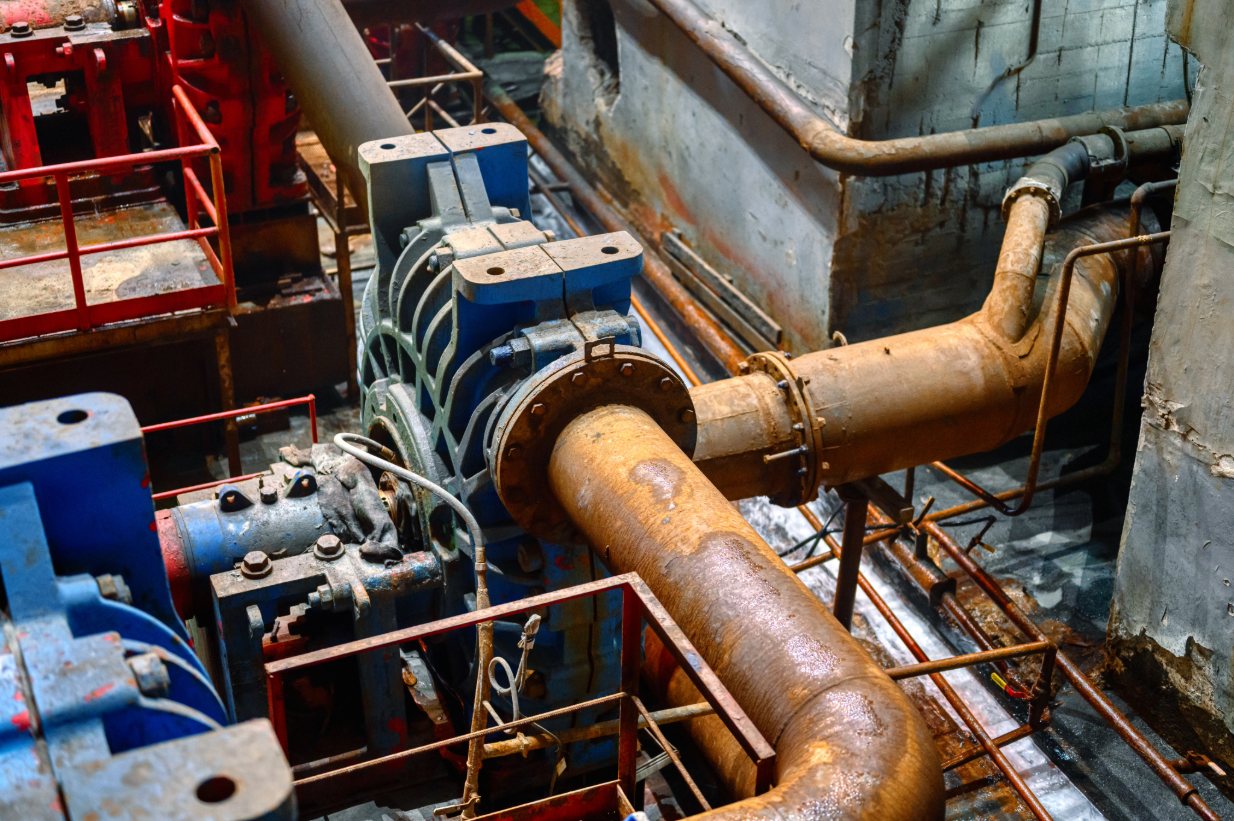

A sludge pump is a heavy-duty pumping device designed to handle liquids containing a high concentration of solids, silt, and other abrasive or viscous materials. Unlike standard water pumps, a sludge pump is specifically engineered to manage challenging applications such as moving thick slurries, wastewater, and settled sediments. These pumps are widely used in industries such as mining, wastewater treatment, dredging, construction, and municipal infrastructure projects, where efficient sludge pumping is essential to maintain operations.

Common Challenges in Sludge Pumping

Sludge handling environments present unique operational difficulties that can affect both performance and equipment longevity:

- High Solid Content and Varying Particle Sizes: Sludge often contains coarse particles, gravel, fibrous materials, and other debris. These materials can restrict flow paths, increase wear, and strain the pump’s components.

- Abrasive and Corrosive Nature of Materials: Industrial sludges frequently include sand, grit, and chemically aggressive compounds. These elements can accelerate impeller and casing wear, reducing overall efficiency and increasing maintenance costs.

- Clogging and Reduced Efficiency in Continuous Operation: Long pumping cycles or high-viscosity sludge can lead to blockages within the pump, resulting in flow interruptions, energy inefficiency, and unplanned downtime.

Where Submersible Sludge Pumps Excel

In demanding environments, a submersible sludge pump offers significant advantages:

- Direct Handling of Solids and Sludge: By operating directly in the fluid, these pumps eliminate the need for extensive suction piping and reduce the risk of air binding. They can efficiently process high-solid materials without the same priming concerns as surface-mounted pumps.

- Reduced Priming Requirements and Space-Saving Design: Submersible units are compact and self-priming by nature, allowing for installation in confined spaces such as pits, lagoons, and tanks. Their design simplifies sludge pumping operations, particularly in mobile or temporary setups.

Types of Impellers Used in Sludge Pumps

The impeller design of a sludge pump plays a decisive role in determining its performance, efficiency, and resistance to clogging. Different impeller types are engineered to handle varying sludge compositions, from fine sediments to fibrous and abrasive solids. Understanding these impeller variations is crucial for selecting the right pump for reliable sludge pumping operations, including applications that require a submersible sludge pump.

Open Impellers

Open impellers feature a simple, straightforward design with vanes attached to a central hub and no enclosing plates.

- Advantages: Easy to clean and maintain, and more tolerant to minor blockages.

- Limitations: Moderate resistance to clogging and lower efficiency in handling highly abrasive or fibrous sludge.

Semi-Open Impellers

Semi-open impellers incorporate a partial back plate, improving their ability to handle solids without excessive wear.

- Advantages: Offers a balance between hydraulic efficiency and solids-handling capability.

- Typical Use: Well-suited for sludge pumping operations where particle sizes vary but the risk of frequent clogging is moderate.

Closed Impellers

Closed impellers are fully enclosed with front and back plates, creating well-defined flow channels.

- Advantages: Deliver higher efficiency, making them ideal for clean or lightly contaminated fluids.

- Limitations: In heavy sludge applications, they are prone to clogging due to restricted passageways.

Vortex / Recessed Impellers

Vortex impellers, also known as recessed impellers, are specifically designed for handling solids and stringy materials. They create a vortex that moves the sludge without solids directly contacting the impeller.

- Advantages: Excellent clogging resistance and minimal wear, making them ideal for high-solid sludge or fibrous materials.

- Trade-Off: Lower efficiency compared to open or semi-open designs due to energy loss in creating the vortex.

- Best Fit: Often used in submersible sludge pumps for difficult or unpredictable solids.

Cutting / Chopper Impellers

Cutting or chopper impellers feature blades or cutting edges that shred fibrous or stringy materials before they reach the pump inlet.

- Advantages: Prevents blockages from rags, hair, or other fibrous debris commonly found in municipal and industrial sludge.

- Application: Ideal for sludge pumping operations where clogging from fibrous materials is a frequent issue.

Choosing the right impeller type for a sludge pump requires evaluating the type of solids, particle sizes, and operational environment. Each impeller design offers unique trade-offs between efficiency, durability, and clogging resistance, which directly influence the pump’s overall performance.

Key Impeller Design Factors Affecting Pump Efficiency

The performance of a sludge pump is heavily influenced by the design and geometry of its impeller. Subtle variations in blade shape, size, and materials can directly affect energy consumption, solids-handling ability, and overall sludge pumping efficiency. For demanding applications, particularly with a submersible sludge pump, these design considerations play a critical role in minimizing downtime and optimizing throughput.

Blade Angle and Curvature

The angle and curvature of impeller blades determine how fluid and solids flow through the pump.

- Impact on Flow Rate: Steeper blade angles can move larger volumes of sludge but may reduce efficiency if solids cause turbulence.

- Energy Considerations: Proper blade curvature ensures smoother flow, reducing energy loss and improving hydraulic performance during continuous sludge pumping.

Impeller Diameter and Width

The dimensions of the impeller directly influence the pump’s hydraulic characteristics.

- Diameter: Larger diameters can generate higher head pressure but may increase energy usage.

- Width: Wider impellers provide more room for solids passage, reducing clogging risk in heavy sludge applications.

- Efficiency Trade-Off: Selecting the right size ensures that the sludge pump balances solids handling with energy efficiency.

Clearances and Tolerances

The gap between the impeller and the pump casing affects both efficiency and clogging resistance.

- Tighter Clearances: Enhance hydraulic efficiency by reducing leakage, but increase the risk of blockages from larger particles.

- Wider Clearances: Improve solids handling, but may slightly reduce efficiency over time.

- Maintenance Impact: Proper clearance adjustment is essential to maintain peak sludge pumping performance.

Material Selection

The durability and efficiency of an impeller are also dependent on the materials used.

- Hardened Alloys: Provide superior abrasion resistance in environments with sand, gravel, and other coarse particles.

- Protective Coatings: Essential for corrosive or chemical-laden sludge, especially for submersible sludge pumps exposed to continuous submersion.

- Optimized Material Choice: Extends the service life of the impeller while sustaining performance under harsh conditions.

Understanding these impeller design factors is key to optimizing pump efficiency and preparing for the next consideration: how these design choices influence clogging resistance in sludge pumping applications.

Impeller Design and Clogging Resistance

Clogging is one of the most common challenges in sludge pumping, particularly when handling thick, abrasive, or fibrous materials. The sludge pump impeller design plays a direct role in determining how efficiently solids can pass through the pump without interruptions. In many cases, a well-designed impeller can reduce unplanned maintenance, energy loss, and operational downtime, especially in submersible sludge pump applications.

Solids Passage Size

The size of the solids passage in an impeller determines its ability to handle large particles without clogging.

- Larger Passages: Allow debris, grit, and sludge solids to move through the pump without getting trapped.

- Application Benefit: Essential for heavy-duty sludge pumping where the material contains rocks, sand, or industrial waste.

- Efficiency Consideration: While large passages improve clogging resistance, they may slightly reduce hydraulic efficiency.

Impact of Fibrous and Stringy Solids

Certain sludge applications, such as municipal wastewater or agricultural slurry, contain rags, fibers, and stringy debris that can entangle impellers.

- Clogging Risk: Standard open or closed impellers may trap these materials, causing frequent blockages.

- Design Adaptation: Specialized impeller shapes and clearances are critical to ensure reliable sludge pump operation under these conditions.

Self-Cleaning and Vortex Designs

Vortex or recessed impellers create a swirling motion that moves solids through the pump without direct contact with the impeller blades.

- Reduced Blockage Risk: By avoiding direct impingement, solids and fibrous materials are less likely to jam.

- Maintenance Advantage: Minimizes manual cleaning and lowers downtime for sludge pumping operations.

Role of Cutter and Agitator Attachments in Submersible Sludge Pumps

Some submersible sludge pumps feature cutting blades or agitators to enhance solids handling.

- Cutter Impellers: Shred fibrous materials before they reach the main impeller, reducing clogging incidents.

- Agitator Attachments: Break up settled sludge at the intake, allowing smoother flow and preventing suction blockages.

- Operational Benefit: These attachments are particularly valuable in applications with high solids concentration or frequent fibrous debris.

The relationship between impeller design and clogging resistance highlights the importance of selecting the right configuration for reliable, low-maintenance sludge pumping. The next consideration involves striking the proper balance between efficiency and clog-free operation.

Efficiency vs. Clogging Resistance: Finding the Right Balance

In sludge pumping applications, there is often a trade-off between maximizing hydraulic efficiency and ensuring reliable solids handling. A sludge pump that delivers peak efficiency in clean or lightly contaminated water may struggle with high-solids or fibrous materials, leading to clogs and downtime. Conversely, pumps designed for maximum clogging resistance may operate at slightly lower efficiency but offer superior reliability in demanding conditions.

Trade-Off Between Efficiency and Solids Passage

- High-Efficiency Impellers: Closed or semi-open impellers are optimized for smooth fluid flow, consuming less energy during operation. However, their narrower passages can be prone to blockages when handling coarse or fibrous sludge.

- Clog-Resistant Designs: Impellers with wider passages or vortex configurations allow larger solids to pass through freely but typically sacrifice some hydraulic efficiency.

Why Vortex and Chopper Impellers Sacrifice Efficiency for Reliability

- Vortex Impellers: Minimize direct contact between solids and impeller blades, dramatically reducing clogging risk. The trade-off is lower energy efficiency due to the swirling flow pattern.

- Chopper Impellers: Cut and shred fibrous debris, preventing blockages during sludge pumping. Energy consumption is slightly higher because of the additional cutting action, but the reliability benefits often outweigh the efficiency loss.

Selecting the Right Sludge Pump for Site-Specific Conditions

Choosing the proper sludge pump requires evaluating the site’s operational demands:

- High-Solids or Fibrous Applications: Favor clog-resistant designs like vortex or chopper impellers, especially in submersible sludge pump installations.

- Moderate to Low-Solids Applications: Pumps with semi-open or closed impellers may provide higher efficiency while maintaining reliable performance.

- Critical Factors to Consider: Solids concentration, particle size, fluid viscosity, and the acceptable trade-off between energy usage and maintenance frequency.

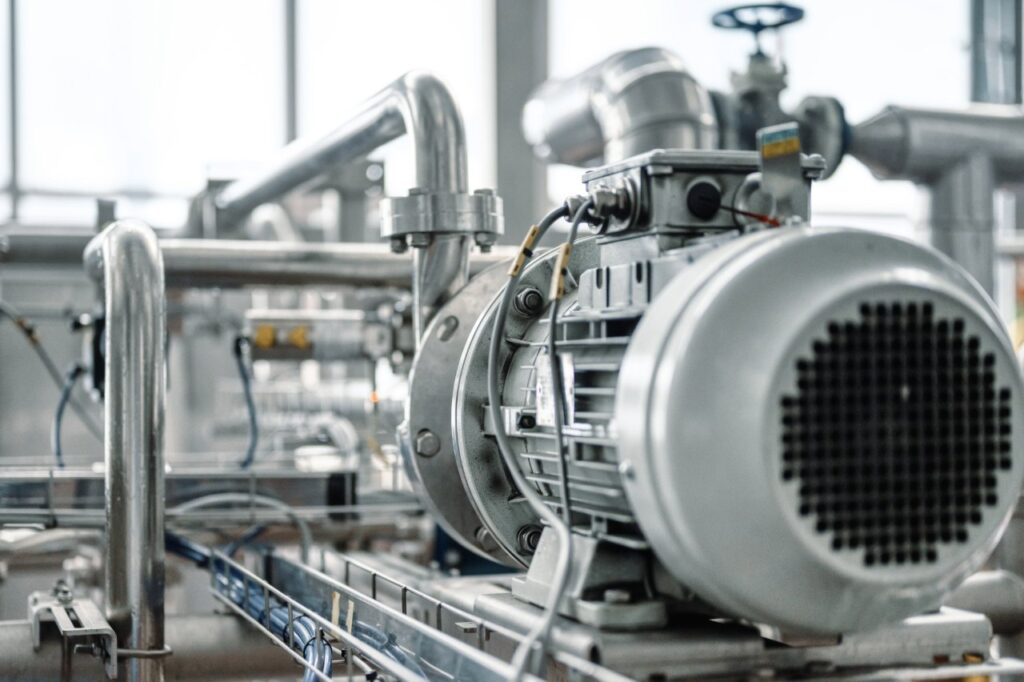

Maintenance and Operational Considerations

Effective maintenance practices are essential to keep a sludge pump operating at peak efficiency and to reduce the risk of unexpected downtime. Impellers, being the primary components for solids handling, require routine attention to ensure consistent sludge pumping performance, especially in high-solids environments.

Routine Inspection of Impellers

Regularly inspecting impellers for wear, erosion, or material buildup is crucial.

- Efficiency Impact: Worn or damaged blades reduce hydraulic efficiency and increase energy consumption.

- Sludge Handling: In a submersible sludge pump, routine inspection helps detect early signs of blockage or surface degradation that can limit solids passage.

Adjusting Clearances to Maintain Peak Performance

The clearance between the impeller and pump casing directly affects both efficiency and clogging resistance.

- Tight Clearances: Maintain higher efficiency but require careful monitoring to avoid blockages.

- Adjustment Benefit: Periodically checking and adjusting clearances ensures the sludge pump continues to handle solids effectively without unnecessary energy loss.

Monitoring for Vibration and Reduced Flow

Early detection of performance issues can prevent costly repairs.

- Vibration and Noise: Often indicate imbalance, buildup, or impending clogging.

- Flow Monitoring: A sudden decrease in flow rate signals obstruction or impeller wear that needs immediate attention to maintain reliable sludge pumping.

Importance of Choosing the Right Impeller for Submersible Sludge Pumps

The longevity and reliability of a submersible sludge pump are directly tied to impeller selection.

- Proper Impeller Type: Reduces downtime by preventing frequent clogging or excessive wear.

- Site-Specific Selection: Ensures optimal solids handling, energy efficiency, and minimal maintenance requirements.

Selecting the Right Sludge Pump for Your Application

Choosing the correct sludge pump for an operation involves more than simply selecting a pump that can move fluid—it requires careful evaluation of the solids being handled and the conditions under which the pump will operate. Making the right selection ensures consistent sludge pumping performance, reduces downtime, and extends equipment life, particularly in demanding environments where a submersible sludge pump is required.

Evaluating Solids Size, Type, and Concentration

The first step in pump selection is understanding the characteristics of the sludge:

- Particle Size: Large solids require impellers with wider passages to prevent blockages.

- Type of Solids: Abrasive particles like sand or gravel demand wear-resistant materials, while fibrous materials require impellers with cutting or vortex capabilities.

- Solids Concentration: Higher concentrations increase the likelihood of clogging and require pumps with robust solids-handling features.

When to Prioritize Efficiency vs. Clogging Resistance

- Efficiency First: For lighter sludge with minimal solids, semi-open or closed impellers offer higher hydraulic efficiency and lower energy consumption.

- Clogging Resistance First: In environments with heavy, stringy, or unpredictable solids, vortex or chopper impellers are preferable even if they sacrifice some efficiency for reliable operation.

- Balancing Both: The ideal choice depends on acceptable energy use, maintenance tolerance, and the criticality of uninterrupted sludge pumping.

Matching Impeller Design to Pumping Conditions

Operational conditions play a major role in final pump selection.

- Submersible Applications: A submersible sludge pump with an agitator or cutter impeller can break up settled solids and prevent intake blockages.

- Surface-Mounted Applications: Pumps with adjustable clearances and high-efficiency impellers work well in controlled environments with predictable sludge properties.

- Custom Fit: Aligning impeller type, material, and clearance settings to site-specific requirements ensures optimal pump performance and longevity.

Impeller Design as the Key to Reliable Sludge Pumping

The performance and reliability of a sludge pump are directly linked to its impeller design. Choosing the right configuration—whether for maximum efficiency, superior clogging resistance, or a balance of both—ensures smoother sludge pumping operations and extended equipment life. For site-specific guidance, professional support, and access to heavy-duty pumping solutions, visit MD Coastal Dredging to explore reliable equipment options tailored to your project needs.