Lagoons play a vital role in various industries, serving as critical components of wastewater treatment, agricultural runoff management, and industrial byproduct containment. Over time, these lagoons accumulate sludge, sediment, and organic waste, which can reduce their efficiency and lead to environmental hazards. Lagoon dredging is the process of removing this accumulated material to restore optimal functionality, improve water quality, and extend the lifespan of the lagoon system.

Regular lagoon dredging is essential for preventing overflow, controlling odors, and maintaining compliance with environmental regulations. Without proper dredging, excess sludge can lead to reduced capacity, inefficient wastewater treatment, and potential contamination of nearby water sources. Effective sludge removal ensures that lagoons continue to operate at peak efficiency, making them crucial for water management in municipal, agricultural, and industrial applications.

Understanding the Need for Lagoon Dredging

How Sediment Buildup Affects Lagoon Efficiency

Over time, lagoons accumulate sediment, sludge, and organic matter, significantly reducing their efficiency. Whether in wastewater treatment facilities, agricultural runoff ponds, or industrial waste storage sites, excessive sediment buildup decreases the lagoon’s holding capacity, leading to frequent overflows and system inefficiencies. Without regular lagoon dredging, these issues can cause operational downtime, increase maintenance costs, and reduce the lagoon’s overall effectiveness.

As sediment accumulates, it creates a thick sludge layer at the bottom of the lagoon, which can interfere with biological treatment processes. In wastewater treatment lagoons, this buildup can hinder the bacterial breakdown of waste, leading to incomplete treatment and an increased risk of contamination. Routine lagoon dredging ensures that the lagoon maintains its designed depth and operational efficiency, preventing costly disruptions and potential environmental hazards.

Impacts of Excessive Sludge Accumulation on Water Quality and Treatment Processes

When sludge levels exceed optimal thresholds, the lagoon’s ability to properly process wastewater and other materials is compromised. Excessive sludge accumulation can lead to several serious consequences, including:

- Increased Oxygen Demand: As organic matter decomposes, it consumes oxygen, which can deplete levels necessary for effective wastewater treatment. This can lead to the release of harmful gases such as methane and hydrogen sulfide, causing foul odors and unsafe working conditions.

- Reduced Hydraulic Retention Time: Lagoons are designed to retain water for a specific period to allow for natural treatment processes. Sludge buildup decreases this retention time, meaning wastewater is not treated thoroughly before being discharged.

- Higher Risk of Algae Blooms: Nutrient-rich sludge can contribute to algae growth, leading to oxygen depletion and poor water quality. This can further affect treatment efficiency and create additional environmental concerns.

- Blockages and System Failures: Thick sludge layers can clog aeration systems, drainage pipes, and pumps, leading to mechanical failures and increased maintenance costs.

By implementing routine industrial lagoon dredging, operators can effectively remove sludge buildup, restore proper lagoon function, and maintain high water quality standards.

Regulatory and Environmental Requirements for Industrial Lagoon Dredging

Industrial lagoon dredging is not just an operational necessity—it is also a regulatory requirement in many industries. Government agencies and environmental organizations impose strict guidelines to ensure that wastewater treatment facilities, agricultural lagoons, and industrial waste ponds do not pose risks to public health or the environment.

Some of the key regulatory and environmental factors affecting lagoon dredging include:

- EPA and Local Compliance: The Environmental Protection Agency (EPA) and local water authorities set limits on discharge quality, nutrient levels, and sludge accumulation. Failure to comply can result in heavy fines and legal action.

- Sediment Disposal Regulations: Once sludge is removed from the lagoon, it must be disposed of properly. Regulations often dictate whether dredged material can be land-applied, treated, or disposed of in specialized facilities.

- Preventing Groundwater Contamination: Lagoons, especially those used in industrial applications, must prevent leachate from seeping into groundwater supplies. Routine industrial lagoon dredging helps maintain lagoon liners and prevents toxic substances from breaching containment.

- Wildlife and Ecosystem Protection: Many lagoon systems are located near wetlands, rivers, or agricultural lands. Effective dredging for lagoon operations minimizes the release of contaminants into surrounding ecosystems, ensuring compliance with conservation laws.

Key Factors in Choosing a Lagoon Dredging Method

Selecting the right lagoon dredging method is essential to ensuring efficiency, cost-effectiveness, and minimal environmental impact. Various factors, including lagoon size, sediment composition, and regulatory constraints, influence which dredge for lagoon projects will be the most suitable. Understanding these considerations helps businesses, municipalities, and industrial facilities choose the most effective industrial lagoon dredging solution for their specific needs.

Lagoon Size and Depth Considerations: Matching the Right Equipment to Project Scale

The size and depth of a lagoon play a crucial role in determining the most efficient dredging method. Larger lagoons with deeper sediment layers require more powerful industrial lagoon dredging equipment, while smaller, shallower lagoons may benefit from more compact, precise dredging solutions.

- Shallow Lagoons (<10 feet deep): Smaller, portable dredges for lagoon systems, such as auger dredgers, are ideal for shallow bodies where precision and minimal disturbance are required.

- Medium-Sized Lagoons (10–20 feet deep): Hydraulic or jet suction dredgers efficiently dredge lagoons, effectively removing sludge without excessive water displacement.

- Large, Deep Lagoons (>20 feet deep): Cutter suction dredgers or mechanical dredgers with extended reach capabilities are better suited for deeper lagoons requiring high-volume sludge removal.

Operators can optimize sediment removal while minimizing operational challenges and costs by choosing the appropriate dredge for lagoon size and depth.

Sediment Composition and Thickness: How Material Type Influences Dredging Approach

The type and thickness of sediment in a lagoon significantly impact the selection of lagoon dredging equipment. Understanding the composition of accumulated sludge allows for a more efficient and targeted dredging approach.

- Soft, Organic Sludge: Hydraulic or suction dredgers work best for lagoons with lightweight organic materials, such as those found in wastewater treatment plants and agricultural lagoons.

- Dense, Compact Sediment: Cutter suction dredgers are ideal for industrial lagoon dredging projects where heavy sediments or solidified sludge layers need to be broken up before removal.

- Contaminated Sludge: Some industrial lagoons contain hazardous waste that must be dredged using sealed containment systems to prevent the spread of pollutants.

Sediment analysis before starting a lagoon dredging project helps determine the best dredging method, ensuring efficiency and compliance with environmental standards.

Environmental Impact and Water Quality Concerns: Ensuring Minimal Disturbance

One of the primary concerns in lagoon dredging is minimizing environmental disruption. Certain dredging methods stir up sediments, potentially affecting water quality, aquatic ecosystems, and surrounding habitats. Therefore, it is critical to choose a dredge that limits turbidity and prevents sediment resuspension for lagoon projects.

- Low-Impact Dredging: Auger dredgers and hydraulic dredgers minimize turbidity, making them suitable for sensitive environments where water quality must be maintained.

- Containment Solutions: In industrial lagoon dredging, geotextile dewatering bags or containment ponds may be necessary to prevent contaminated sludge from re-entering the water system.

- Regulatory Compliance: Many projects must adhere to strict environmental guidelines, requiring careful selection of lagoon dredging methods that meet legal and ecological standards.

By implementing best practices for industrial lagoon dredging, businesses and municipalities can efficiently remove sludge while protecting natural resources and maintaining water quality.

Budget and Project Timeline: Evaluating Cost-Effective Solutions

Cost and time constraints are significant factors in any lagoon dredging project. The right dredging method should balance efficiency with affordability while ensuring long-term lagoon functionality.

- Operational Costs: Hydraulic dredging is often more cost-effective for large-scale industrial lagoon dredging projects, while mechanical dredging can be more expensive due to labor and equipment costs.

- Project Duration: When time-sensitive lagoon maintenance is required, faster dredging methods, such as jet suction dredging, may be preferable.

- Long-Term Maintenance: Investing in the right dredge for lagoon projects can reduce the frequency of dredging cycles, leading to long-term cost savings.

Common Lagoon Dredging Methods

Different lagoon dredging methods are used based on lagoon size, sediment composition, environmental constraints, and project goals. Choosing the right dredge for lagoon operations ensures maximum efficiency, minimal disruption, and compliance with regulatory requirements. Below are the most commonly used industrial lagoon dredging methods, each with its benefits and challenges.

Hydraulic Dredging for Lagoons

How Hydraulic Dredging Works for Industrial Lagoon Dredging

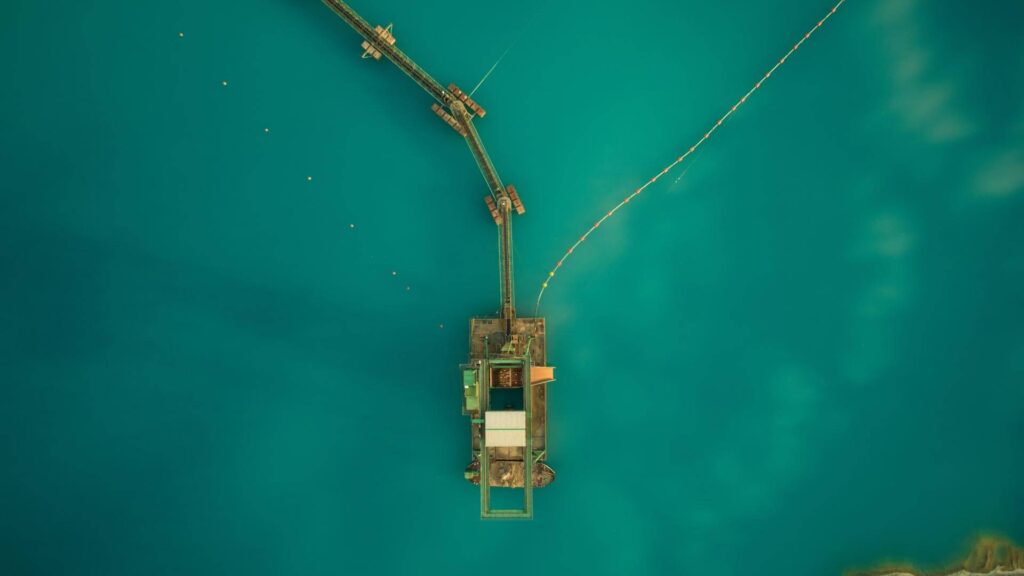

Hydraulic dredging is one of the most efficient methods for removing accumulated sludge from lagoons. This technique involves using a dredge for lagoon operations that pump sediment-laden water through a suction system, transferring the material to a disposal or dewatering site. The process is ideal for large-scale industrial lagoon dredging, where continuous sediment removal is required.

Best Applications

- Large wastewater treatment lagoons: Ensures continuous operation without the need for draining the lagoon.

- Agricultural waste lagoons: Effectively removes manure sludge and nutrient-rich deposits.

- Industrial processing lagoons: Safely extracts sediments from chemical and food processing wastewater systems.

Benefits

- Continuous operation: No need to drain the lagoon, allowing for uninterrupted use.

- Efficient sludge removal: Removes both soft organic sludge and finer sediments effectively.

- Minimal disruption: Creates low turbidity and minimizes disturbance to surrounding areas.

Challenges

- High water content in dredged material: Requires additional dewatering processes such as geotextile tubes or settling ponds.

- Disposal considerations: Transporting and handling dredged material can add costs and regulatory compliance requirements.

Mechanical Dredging for Lagoons

Process of Using Excavators, Clamshell Dredges, and Other Mechanical Methods

Mechanical lagoon dredging involves physically removing sediment using heavy-duty equipment such as long-reach excavators, clamshell dredges, or draglines. This method is particularly effective for industrial lagoon dredging projects with dense or compacted sediments.

Best Applications

- Shallow lagoons: Ideal for wastewater treatment ponds with easily accessible sediments.

- Dewatered or dried-out lagoons: Perfect for lagoons that have been drained or naturally dried.

- Industrial lagoons with heavy sediments: Removes dense materials such as sand, sludge, and industrial byproducts.

Benefits

- Precise removal: Allows for targeted dredging, reducing unnecessary material disturbance.

- Effective for heavy sediments: Easily removes thick sludge, debris, and compacted materials.

- Versatile equipment options: Can be adapted for various dredges for lagoon applications.

Challenges

- Requires temporary drainage: Often necessary to lower water levels or completely drain the lagoon.

- Increased labor costs: Requires skilled operators and additional equipment for sediment transport and disposal.

Cutter Suction Dredging

How Cutter Suction Dredgers Work in Lagoon Dredging

Cutter suction dredgers (CSDs) combine hydraulic and mechanical dredging by using a rotating cutter head to break up compacted sediments before suctioning them out. This method is ideal for lagoon dredging projects with hardened or highly compacted sludge layers.

Best Applications

- Heavily compacted or hardened sediments: Removes solidified organic waste and industrial sludge.

- Large-scale industrial lagoons: Provides high-volume dredging for deep, sediment-filled lagoons.

- Municipal wastewater treatment lagoons: Clears obstructions and restores holding capacity.

Benefits

- Powerful cutting mechanism: Easily breaks through dense sludge layers.

- Efficient deep sediment removal: Extracts sediment from the bottom of large lagoons.

- High productivity: Removes large volumes of sediment quickly, making it ideal for urgent projects.

Challenges

- Higher operational complexity: Requires skilled operators to control the cutter head and suction system.

- Requires specialized equipment: Cutter suction dredgers are larger and may not be suitable for small-scale lagoon dredging.

Auger Dredging for Lagoons

How Auger Dredges Provide Targeted Industrial Lagoon Dredging

Auger dredging uses a rotating horizontal auger to loosen sediment while simultaneously vacuuming it up for removal. This method is highly precise, making it ideal for industrial lagoon dredging projects in sensitive environments.

Best Applications

- Precision dredging in lined lagoons: Protects synthetic or clay liners from damage.

- Municipal and industrial wastewater treatment lagoons: Ideal for controlled sludge removal.

- Agricultural lagoons: Effectively removes manure sludge while maintaining nutrient balance.

Benefits

- Minimal turbidity: Reduces sediment resuspension, maintaining water quality.

- High sediment capture efficiency: Directly removes sludge without excessive water intake.

- Best for sensitive environments: Ensures lagoon integrity while conducting lagoon dredging.

Challenges

- Limited reach: Auger dredgers may not be suitable for deep lagoons or extensive sediment layers.

- Lower capacity compared to hydraulic or cutter suction dredging: Not ideal for large-scale sludge removal.

Choosing the Right Dredge for Lagoon Projects

Selecting the right dredge for lagoon operations is essential for ensuring effective dredging while maintaining cost efficiency and minimizing environmental impact. Various dredging technologies are available, so understanding which method best suits the project’s needs is crucial for successful industrial lagoon dredging.

Comparing Different Dredging Technologies Based on Project Needs

Different lagoon dredging technologies offer unique advantages depending on the size of the lagoon, the type of sediment, and operational constraints. Hydraulic dredging, for example, is ideal for large-scale industrial lagoon dredging, as it continuously pumps sludge through pipelines for transport and disposal. This method is commonly used for wastewater treatment lagoons and agricultural waste lagoons, where efficiency and minimal disruption are critical.

Mechanical dredging, on the other hand, involves physically removing sediment using excavators, clamshell dredgers, or other heavy equipment. This method is best suited for lagoons that can be temporarily drained or where sediment is too dense for hydraulic dredging. While mechanical dredging allows for the precise removal of heavy materials, it often requires additional labor and equipment for transport.

For heavily compacted sediment, cutter suction dredging is a highly effective solution. This method combines a rotating cutter head with a powerful suction system to break up and extract solidified sludge. Cutter suction dredging is commonly used in industrial lagoons where deep, dense deposits need to be removed efficiently. However, due to its complexity, it requires specialized equipment and experienced operators.

Auger dredging is another option, particularly for lined lagoons or areas where environmental protection is a priority. Auger dredgers use a rotating screw-like mechanism to loosen sediment while vacuuming it up, making them ideal for industrial lagoon dredging in sensitive environments. This method minimizes turbidity, reducing the risk of sediment resuspension. However, its reach is more limited compared to hydraulic or cutter suction dredging, making it better suited for targeted sludge removal.

Each of these dredging technologies serves a specific purpose, and selecting the right one depends on the project’s size, sediment type, and operational goals.

Factors to Consider When Selecting a Dredge for Lagoon Cleaning

Several factors should be evaluated when choosing the best dredge for lagoon maintenance to ensure efficient and cost-effective operations.

- Lagoon Size and Depth

- Smaller, shallow lagoons are best dredged using auger or mechanical dredging methods.

- Larger, deeper lagoons require hydraulic or cutter suction dredgers for high-volume sludge removal.

- Sediment Composition

- Soft organic sludge is most effectively removed with hydraulic dredging.

- Dense or compacted sediment requires a cutter suction dredger for efficient extraction.

- Lagoons containing hazardous or contaminated materials may need specialized dredging techniques to prevent the spread of pollutants.

- Environmental Regulations

- Some industrial lagoon dredging projects must comply with strict environmental laws regarding sediment removal and disposal.

- Lined lagoons require non-disruptive dredging methods, such as auger dredging, to prevent damage to containment systems.

- Proper disposal of dredged material must be planned to meet regulatory requirements.

- Operational Costs and Efficiency

- Hydraulic dredging minimizes labor costs by automating sludge removal, making it cost-effective for large-scale projects.

- Mechanical dredging requires additional workforce and transport logistics, which can increase expenses, but it is effective for precise sediment removal.

- The frequency of dredging cycles should also be considered, as investing in a high-efficiency dredge for lagoon maintenance can reduce long-term costs.

- Disposal and Dewatering Requirements

- Hydraulic dredging produces a high water content in dredged sludge, which requires dewatering methods such as geotextile tubes or settling ponds.

- Mechanical dredging results in drier material, which may be easier to transport and dispose of.

Carefully assessing these factors ensures that the most suitable lagoon dredging method is selected, balancing efficiency, cost, and environmental responsibility.

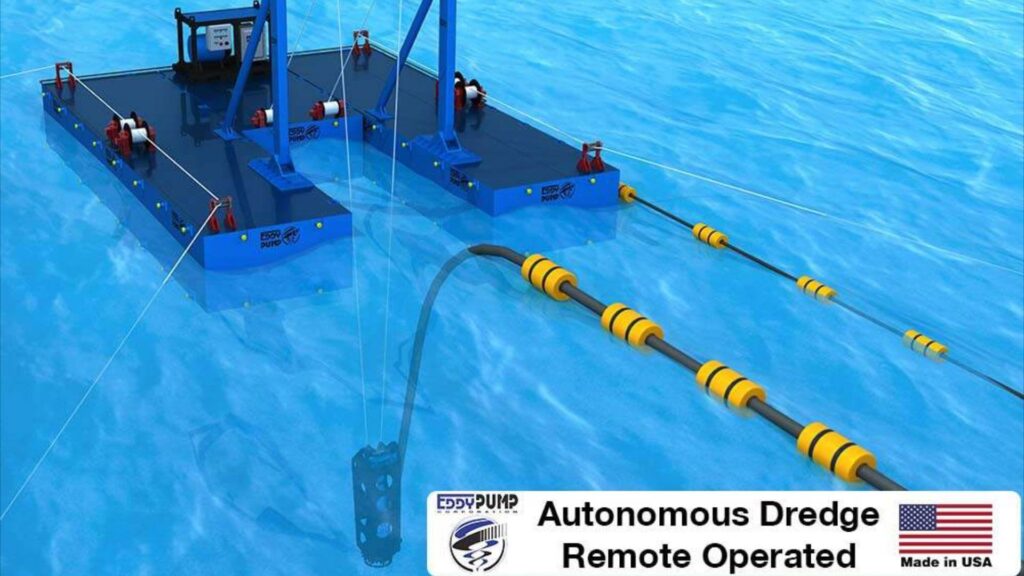

The Role of Automation and GPS in Modern Lagoon Dredging

Modern industrial lagoon dredging has evolved with advancements in automation and GPS technology, allowing for greater precision and operational efficiency. These innovations enhance lagoon dredging by reducing manual labor, increasing accuracy, and optimizing sediment removal processes.

- GPS-Guided Dredging

- GPS technology enables real-time mapping of sediment layers, ensuring that only targeted areas are dredged.

- This precision reduces unnecessary material removal, optimizing efficiency while lowering costs.

- Automated Dredging Systems

- Many modern dredgers are equipped with automated controls, allowing for remote operation and monitoring.

- Automation improves dredging accuracy and reduces the need for on-site personnel, lowering operational risks and expenses.

- Real-Time Monitoring and Reporting

- Advanced dredging systems provide continuous tracking of sludge removal rates and progress.

- Digital reporting tools help operators comply with environmental regulations by documenting sediment disposal and water quality impact.

Sustainable Practices in Industrial Lagoon Dredging

As industries and municipalities focus on environmentally responsible operations, sustainable lagoon dredging has become a priority. Traditional industrial lagoon dredging methods often generate large volumes of sludge that require proper disposal, increasing environmental concerns. By implementing eco-friendly dredging techniques, responsible sludge management, and innovative material reuse strategies, businesses can reduce their environmental footprint while maintaining efficient lagoon dredging operations.

Eco-Friendly Sludge Management and Dewatering Techniques

Effective sludge management is critical for sustainable industrial lagoon dredging. One of the biggest challenges in lagoon dredging is handling the high water content in dredged material. If not managed properly, excessive water in dredged sludge can complicate disposal, increase transportation costs, and contribute to environmental contamination.

To mitigate these issues, industries are adopting modern sludge dewatering techniques, including:

- Geotextile Dewatering Bags

- These large, permeable bags allow water to drain from the sludge while retaining solid material.

- The filtered water can often be treated and returned to the lagoon, reducing overall water loss.

- This method minimizes the environmental impact by preventing excessive sludge runoff.

- Centrifuge Dewatering

- High-speed centrifuges separate water from sludge, significantly reducing the volume of material that needs to be transported or processed.

- This method is commonly used in industrial lagoon dredging, where quick sludge drying is necessary.

- Settling Ponds and Drying Beds

- In some cases, dredged sludge is pumped into designated drying beds or settling ponds where water is gradually drained or evaporated.

- This technique is cost-effective but requires sufficient land space and time for drying.

By integrating these dewatering techniques into lagoon dredging operations, industries can minimize waste, reduce handling costs, and comply with environmental regulations.

Reuse and Disposal of Dredged Material: Agricultural, Industrial, and Landfill Options

After lagoon dredging, proper sludge disposal or repurposing is essential for maintaining environmental sustainability. Depending on the composition of the dredged material, it can be repurposed in several ways, including:

- Agricultural Reuse

- In industrial lagoon dredging, if the sludge contains nutrient-rich organic matter (such as from agricultural lagoons or wastewater treatment plants), it can be repurposed as a soil amendment.

- Proper testing and treatment ensure the sludge is free of contaminants before being used in farming applications.

- Farmers can utilize this organic material as fertilizer, reducing the need for chemical inputs and promoting soil health.

- Industrial Applications

- Some dredges for lagoon projects produce sludge with high sand or clay content, which can be used as construction materials or for land reclamation.

- Industrial byproducts from dredged materials can be processed for use in brickmaking, cement production, and land stabilization projects.

- Landfill Disposal

- When sludge is contaminated with heavy metals or hazardous materials, disposal in a regulated landfill is often required.

- Proper classification and treatment are essential to ensure safe containment and compliance with environmental guidelines.

By identifying opportunities for reuse, industries can turn lagoon-dredging waste into valuable resources, reducing landfill dependency and promoting sustainability.

Reducing Environmental Impact Through Innovative Lagoon Dredging Solutions

Advancements in lagoon dredging technology have made it possible to minimize ecological disruption while maintaining efficiency. Innovative approaches help reduce sediment resuspension, protect water quality, and optimize sludge removal.

- Precision Dredging with GPS and Automation

- GPS-guided dredge for lagoon projects ensures precise sediment removal, reducing unnecessary dredging and habitat disturbance.

- Automated dredging systems optimize efficiency, reducing fuel consumption and operational waste.

- Low-Turbidity Dredging Techniques

- Auger dredging and hydraulic dredging minimize water column disturbance, ensuring that sediments remain contained rather than spreading into the surrounding water.

- This technique is particularly beneficial for lined lagoons and environmentally sensitive areas.

- Closed-Loop Dredging Systems

- Some industrial lagoon dredging projects implement closed-loop systems, in which dredged material is processed on-site to separate solids from water efficiently.

- This reduces water wastage, prevents contamination, and minimizes sludge transportation costs.

Conclusion

Effective lagoon dredging is crucial for maintaining wastewater treatment systems, agricultural waste lagoons, and industrial retention ponds. Over time, sediment buildup and sludge accumulation can hinder lagoon efficiency, leading to operational inefficiencies and environmental concerns. Various industrial lagoon dredging methods, such as hydraulic, mechanical, cutter suction, and auger dredging, offer tailored solutions depending on the size of the lagoon, sediment type, and project goals. Selecting the appropriate dredge for lagoon maintenance ensures efficient sludge removal while minimizing environmental impact and operational disruptions. Advanced dredging technologies, including automation and GPS-guided dredging, have further improved precision, reducing costs and enhancing overall efficiency.

Sustainability in industrial lagoon dredging has become a top priority, with industries and municipalities seeking eco-friendly sludge management and responsible disposal solutions. The use of dewatering techniques, sediment reuse strategies, and low-turbidity dredging methods helps minimize waste while maintaining compliance with environmental regulations. By choosing the right dredge for lagoon projects and implementing innovative dredging practices, operators can achieve long-term lagoon performance while reducing their ecological footprint. Efficient and sustainable lagoon dredging not only restores lagoon functionality but also contributes to improved water management and environmental conservation.